Vinyl Life Expectancy

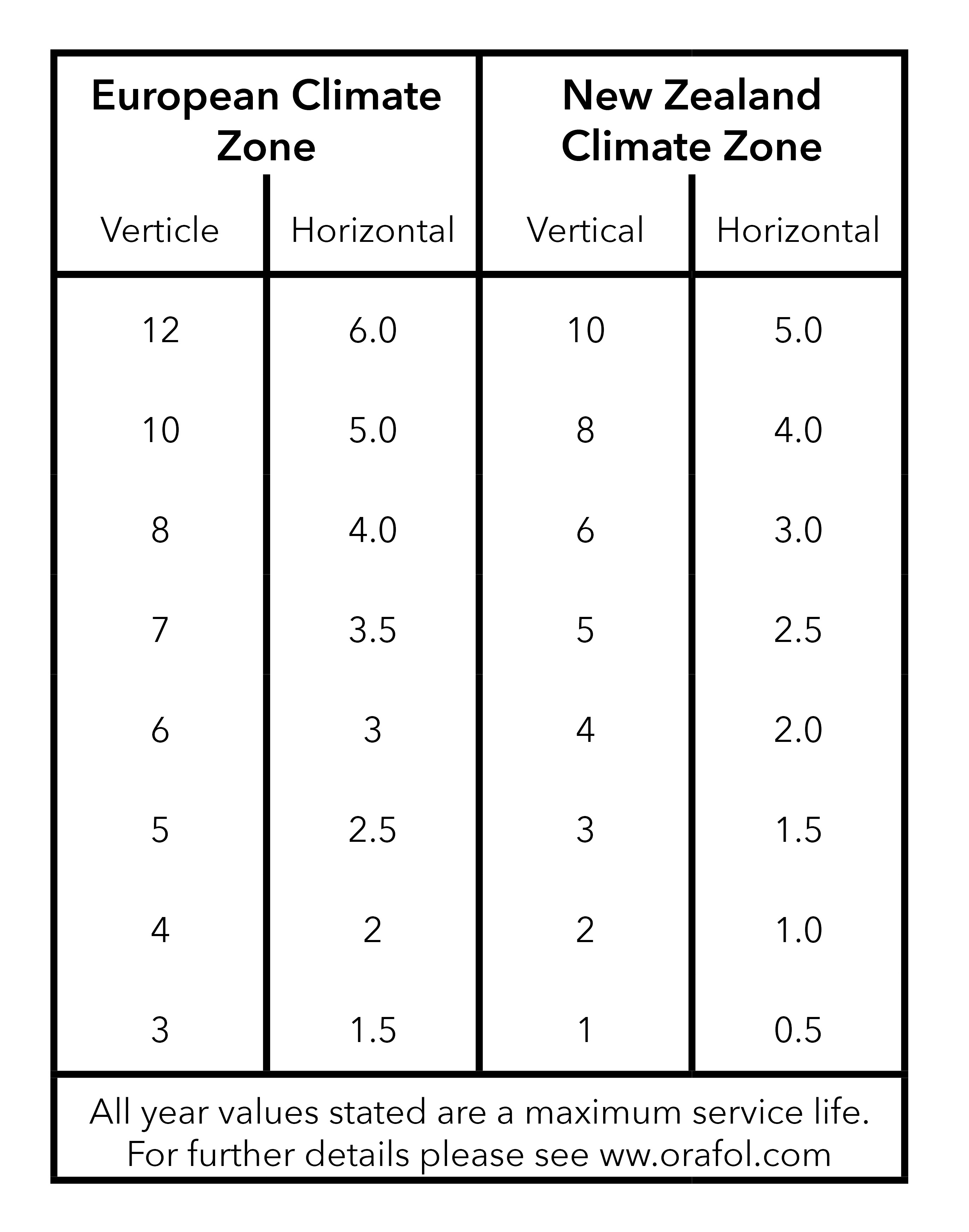

All year ratings on the site are based on the suppliers specifications and they relate to the maximum life expectancy of the vinyl on the vertical surface in Central European conditions. In New Zealand, due to harsher UV and environmental conditions, the vinyl is not expected to last aslong and so Orafol have produced a chart to guide you through their maximum service life for our conditions.Even with the chart below, it is important to point out to your customers that there are many factors that can affect the life of vinyl, so it may not reach the maximum life listed in the chart. We have given some examples below of additional factors that your customers should be aware of that affect vinyl life.

How to read "The Chart"

The numbers in Red on the left are the ones used in the colour charts and spec sheets. Using the example of the Oracal 751 Black, with the chart you can see it changes to 6 years vertical and 3 years horizontal as its maximum life expectancy in NZ conditions. These numbers are the maximum service life under normal conditions outdoors. If for example you are using your 751 Black indoors away from UV you may get more life out of it, dependant on the application. The reason the horizontal number is significantly different is because it is based on the worst case scenario like the bonnet of your car, exposed to baking sun all day long. The next question then is when does vertical turn into horizontal? Most suppliers, like Orafol, 3M etc, say that once a sign has moved +/- 10° from vertical it is now “Non-vertical”.The all important "Other Factors"

Within the layers that make up our Mono, Polymeric and Cast Vinyls is a cover layer of Gloss. This gloss layer is what keeps the damaging UV out for as long as possible. But from day one it is getting attacked, some of the more common issues we see with signage is Dirt on the surface, Scratching and Waxes.Dirt

Vinyl is porous, contaminants left on its surface for long periods of time will etch into the vinyl and damage the vinyl irreversably from the inside. This often looks like little burn marks. Cleaning dirty signage is a must.Scratching

The top surface of gloss has a hard enough time protecting the film as is without being put through car washes, cleaning with a hard brush and other methods that scratch the surface. Sponge cleaned by hand with a very mild cleaning product is highly recommended wiping when finished with a microfibre cloth.Wax

Some waxes can dry out the surface of the vinyl and can cause it to crack over prolonged use. A lot of waxes and polishes come with a cutting agent included (cut and polish), the more expensive brands tell you that its there and more importantly when its not there. Some of the cheaper products don’t tell you the cutting agent is included and using a product with this agent can badly damage the surface of your vinyl. You may think your wax and polish is protecting your print but you are actually causing it major damage.Due to the wide variety of possible uses and applications customers should independently determine the suitability of any material for their specific purpose, prior to use. All information above is intended only as a guide and is given without guarantee and does not constitute a warranty.